AKTD Thermic Degasifiers - General Features

- In steam and hot water systems, there are two important effects causing to corrosion and deformation. The hardness and stone causing materials like lime in the water and Oxygen (02) and carbon dioxide (CO2) gases.

- Steam boiler feed water, and free oxygen (02) present as dissolved in hot water boilers, carbon dioxide (CO2) gases formed by the decomposition of carbonates in the boilers cause corrosionsü boilers, in the device using steam and especially in the plants in the form of pores and dissolutions by rusting. The effects of these gases further increase as fresh feed water ratio and system operating pressure increases.

- If boiler feed water oxygen is not purifi ed from these gases, the life of all system is shortened and even in a very short time, corrosions and perforations may occur in the boiler and the device and facilities forming the system. Besides this, CO2 causes excessive corrosions especially in the devices using steam and serpentines and in condense pipes.

- In order to purify boiler feed water from 02 and CO2 gases, they are compulsory to be degased by passing from degasifier device.

- Classical thermal degasifi ers operating based on temperature positive (+) pressure principle are especially used in high pressure systems having high fresh feed water ratio. These devices provide the carbohydrates fragmented in condense tank in part with fragmenting in their own body and with releasing their gases. Operating temperature of these devices is from 102°C to 105°C, and the operating pressure is at the level of 0,2 bar- 0,5 bar and degasing effi ciency of them is at the range from 96% to 100%. Since the temperature is high, in order to provide the boiler feed pumps with operating without causing cavitation, the installation of the pumps at least in 4m-4.5 m height is compulsory. In this type of degasser system, another part of heating steam is released to the water in the degasser tank through special mixture equipment and degasing again is prevented.

- Degasser system consists of a few devices, fi xtures and necessary installations for their connections.

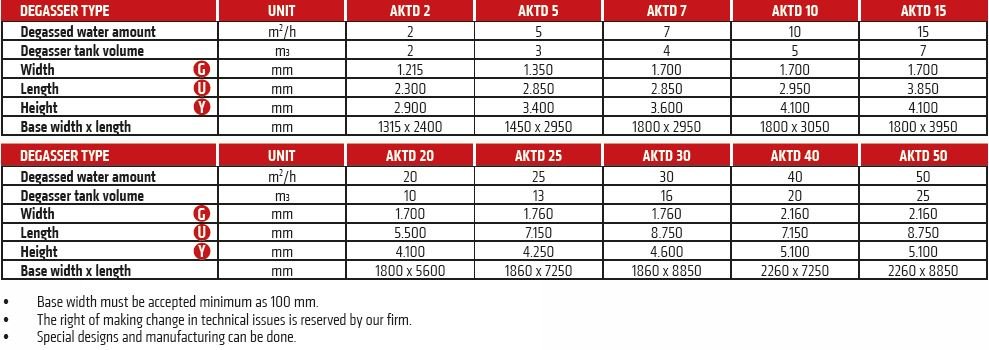

AKTD Thermic Degasifiers - Technical Dimensions